What We Do

We develop optimization software for real-time control, machine learning, and factory logistics. Our research focuses on both the theory and implementation of optimization algorithms.

Our team consists of researchers active in the continuous and discrete optimization communities. We also work at the intersection of optimization and machine learning.

Our solutions have been deployed to Toyota Motor Corporation (TMC) vehicles and factories.

Our customers include vehicle designers, control engineers, and warehouse managers.

The Challenges

Different applications pose different challenges. When deployed to real-time control systems, optimization algorithms must meet very stringent requirements on run-time and reliability. In factory logistics, the underlying optimization problem is usually NP-hard, so it requires clever approximation methods.

Tools & Optimization Projects

Code-generation for real-time control

Modern vehicle control software relies on the high-speed solution of optimization problems. To meet these speed requirements, we have developed novel code-generation tools that customize the implementation to the specific run-time environment. TUS Patent “Systems and Methods for Automatically Generating Solver Code for Nonlinear Model Predictive Control Solvers”

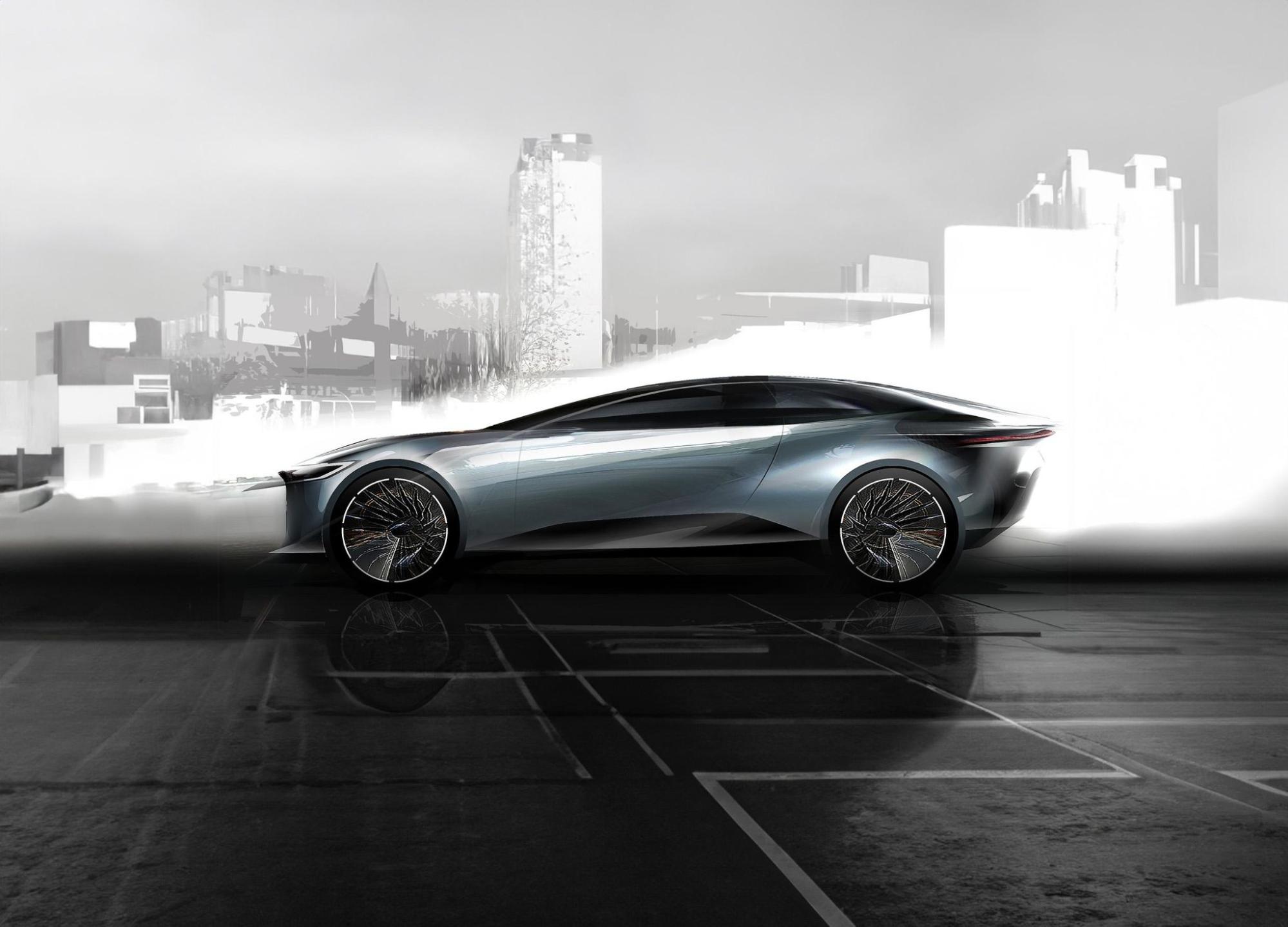

Generative AI for Design Optimization

Currently, designers can leverage publicly available text-to-image generative AI tools as an early step in their creative process. In collaboration with TRI’s Human-Centered AI research division, we developed enhanced image generation tools that allow users to also optimize performance metrics, like vehicle drag coefficient. Ultimately, this cuts down the iterations needed to reconcile design and engineering considerations.

Further Information

- Convex synthesis and verification of control-Lyapunov and barrier functions with input constraints

- Bridging Design Gaps: A Parametric Data Completion Approach With Graph Guided Diffusion Models

- VehicleSDF: A 3D generative model for constrained engineering design via surrogate modeling

- Surrogate Modeling of Car Drag Coefficient with Depth and Normal Renderings

- Data-driven Car Drag Coefficient Prediction with Depth and Normal Renderings