Summary

Toyota Research Institute (TRI) developed an open-source Battery Evaluation and Early Prediction (BEEP) platform to accelerate battery testing.

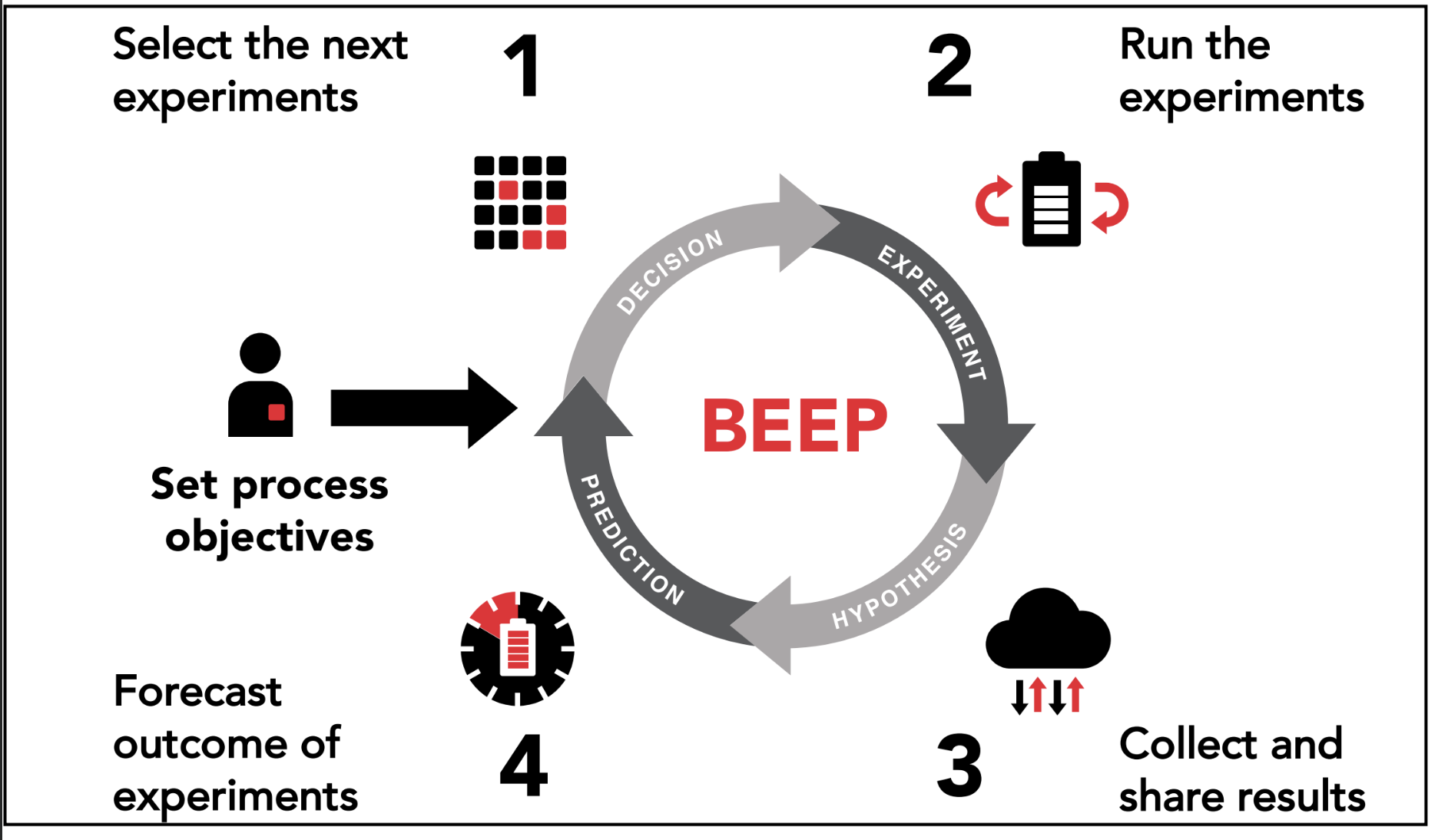

BEEP automates battery cycling experiments and automatically stores the data in a structured way for machine learning. Within the platform, researchers guide overall objectives while the algorithm runs constantly to make the experiments as efficient and autonomous as possible. The software interface enables researchers to monitor and control experiments anywhere.

BEEP also addresses bottlenecks in the battery development process by making early outcome predictions to reduce testing time and conduct closed-loop optimization (CLO) to minimize the total number of experiments. Typical battery cycling experiments take months or years to complete. In contrast, BEEP provides early prediction to enable accurate forecasting of the outcome of a battery cycling experiment without having to run every experiment to completion. This predictive capability can also bin or sort cells into various categories (e.g., good, bad), potentially useful for quality control and other in-line manufacturing processes.

Batteries require many manufacturing processes and control parameters, resulting in a vast combinatorial space that needs to be explored to optimize performance. Closed-loop optimization (CLO) addresses the challenge of using Bayesian optimal experimental design (OED) to adaptively sample the parameter space, programmatically suggesting new parameters and test conditions to identify the optimal values quickly.

BEEP is actively used at Stanford University to manage battery experiments. The platform is highly modular and scalable and can be run on cloud infrastructure or standalone, air-gapped systems. Its hybrid architecture manages data using high-performance databases and data lakes containing standardized files, supports several industrial battery tester systems, and can be extended to new systems.

Medium Blog

"Understanding the complexity of battery health with explainable AI." By Shijing Sun, Amalie Trewartha, and the TRI Energy & Materials research division. (2023).

Documentation

https://tri-amdd.github.io/beep/

https://pypi.org/project/beep/

Severson, K., P. Attia, N. Jin, Z. Yang, N. Perkins, M. Chen, M. Aykol, P. Herring, S. Harris, W. Chueh, and R. Braatz. “Data-driven Prediction of Battery Cycle Life Before Capacity Degradation.” Nature Energy, 2019.

Herring, P. “BEEP: A Python Library for Battery Evaluation and Early Prediction” et al. SoftwareX (2020).

Attia, P., A. Grover, N. Jin, K. Severson, T. Markov, Y. Liao, M. Chen, B. Cheong, N. Perkins, Z. Yang, P. Herring, M. Aykol, S. Harris, R. Braatz, S. Ermon, and W. Chueh. “Closed loop Optimization of Extreme Fast Charging of Batteries Using Machine Learning.” Nature. 578, pp. 397–402 (2020).

Vlijmen Bvan, Lam V, Asinger PA, Cui X, Ganapathi D, Sun S, et al. Interpretable Data-Driven Modeling Reveals Complexity of Battery Aging. ChemRxiv. Cambridge: Cambridge Open Engage, 2023.